Product Introduction

Filters for removing volatile organic compounds (VOCs) and odors emitted at low concentrations from organic solvents, chemical products, printings, paints, gases, plastics, etc.

Specifications and Standards

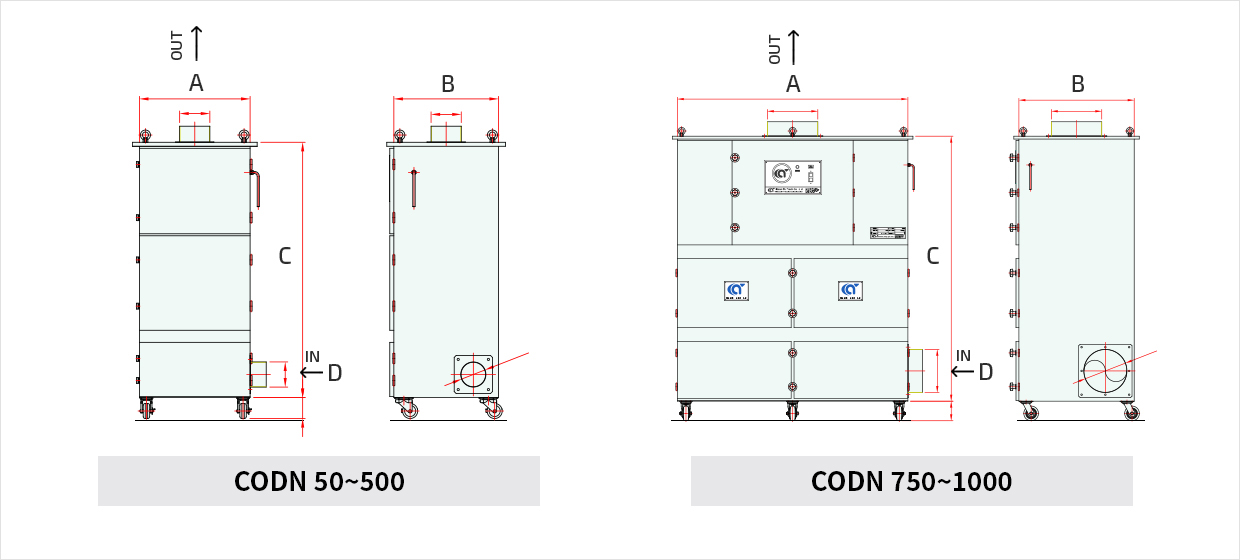

Appearance

Product Specifications

| Model Name | Air Volume (CMM) |

Static Pressure (mmAq) |

Power Output (Kw) |

Standards | Activated Carbon (Kg) |

|||

|---|---|---|---|---|---|---|---|---|

| Width(A) | Depth(B) | Height(C) | Inlet(D) | |||||

| CODN-50 | 7 | 230 | 0.75 | 460 | 500 | 1100 | Ø100 | 20 |

| CODN-100 | 12 | 200 | 0.75 | 550 | 520 | 1270 | Ø125 | 20 |

| CODN-200 | 25 | 230 | 1.5 | 670 | 650 | 1630 | Ø150 | 38 |

| CODN-300 | 40 | 230 | 2.2 | 780 | 760 | 1750 | Ø200 | 60 |

| CODN-500 | 60 | 230 | 3.7 | 800 | 750 | 1970 | Ø250 | 66 |

| CODN-750 | 80 | 250 | 5.5 | 1600 | 800 | 1840 | Ø300 | 115 |

| CODN-1000 | 100 | 250 | 7.5 | 1700 | 800 | 2050 | Ø350 | 130 |

※ Specifications are subject to change for performance improvement.

Key Features

-

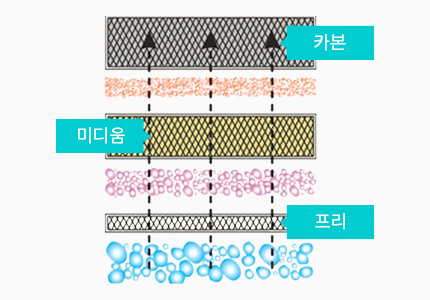

Three-stage Filter Structure

- The three-stage filter structure enhances the removal efficiency of particles and volatile organic compounds (VOCs) and extends the filter's lifespan.

- To maximize the filter's performance, it is designed to be filtered in the order of ① Pre-filter ② Medium Filter ③ Carbon Filter.

-

Stage 1: Pre-filter

- A pre-filter is installed to extend the life of the high-performance filter mounted downstream.

- The polyester material pre-filter removes large particles as a first step.

-

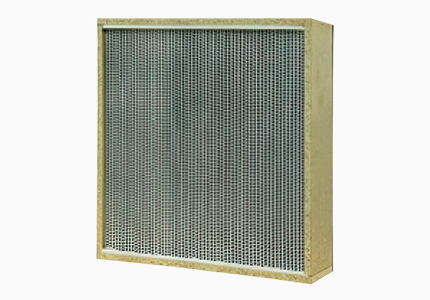

Stage 2: Medium Filter

- It secondarily removes particles not filtered by the first-stage pre-filter.

- The MEDIUM filter, depending on the MEDIA chosen, can achieve filtering efficiencies ranging from 65% to 95%, offering a mid to high-performance filter capable of meeting various filtering needs.

-

Stage 3: Carbon Filter

- Finally removes volatile organic compounds and odors that have passed through the first and second filters.

- The Carbon filter uses activated carbon to physically and chemically adsorb and absorb volatile organic compounds and odors.

- Activated carbon is made from coconut shell charcoal subjected to chemical and physical heat treatment at 600~900˚C, and it has an internal surface area of about 1,200㎡ per gram, making it highly effective in adsorbing odors and gases for air purification.

-

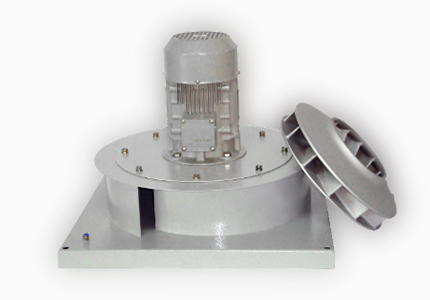

High-efficiency Turbofan

- Uses a durable high-efficiency turbofan to deliver stable and superior suction performance.

- The impeller is processed with ultra-precision electronic balancing to minimize vibration and noise.

Options (Selectable)

-

Control Box / Distribution Panel

Control Box / Distribution Board

- Switches and breakers, control devices are configured in a separate steel plate box.

- The electrical control device is not affected by contaminants, extending its life.

- It can be attached and used at the desired location.

-

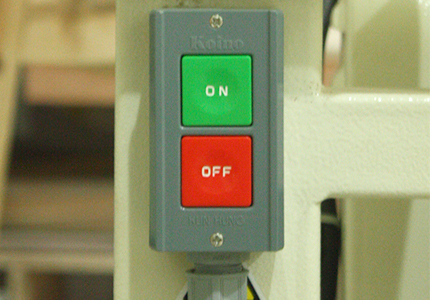

Local Switch, Contact Configuration

- A local switch for turning the power ON/OFF is added.

- It can be attached and used at the desired location.

- The electrical circuit's contacts can be configured to turn ON/OFF simultaneously with other equipment.

-

Flexible Conduit for Wiring

- Covering the wires with a flexible conduit prevents fire caused by damage to the insulation.

-

Customization / Custom Design

- Design changes to non-standard specifications or new developments are possible upon request.

- We possess industry-leading design responsiveness.

-

Power Specification Changes

- Options include 220V/ 380V/ 440V, single-phase/three-phase, 50Hz /60Hz.

Precautions

-

- Not suitable for high concentrations of volatile organic compounds and odors.

- If the facility emits air pollutants, it is necessary to use the Adsorption Tower SAC-Series, which requires permit and authorization.