Product Introduction

A centralized oil mist collector for CNC lathes, machining centers, robodrills, honing machines, tapping machines, and electrical discharge machines, effectively removing large amounts of oil mist generated. The models are divided into CMC and CMCE, which basically have the same structure and performance, but the CMCE is equipped with an additional third-stage filter.

Specifications and Standards

Appearance

Product Specifications

| Model Name | Air Flow (CMM) |

Static Pressure (mmAq) |

Power (Kw) |

Specifications | |||

|---|---|---|---|---|---|---|---|

| Width(A) | Depth(B) | Height(C) | Suction Port(D) | ||||

| CMC(E)-200 | 25 | 230 | 1.5 | 790 | 720 | 1550(1760) | Ø160 |

| CMC(E)-300 | 40 | 230 | 2.2 | 790 | 760 | 1650(1910) | Ø210 |

| CMC(E)-500 | 60 | 230 | 3.7 | 790 | 760 | 1737(2137) | Ø260 |

| CMC(E)-750 | 80 | 250 | 5.5 | 1500 | 850 | 1807(2097) | Ø310 |

| CMC(E)-1000 | 100 | 250 | 7.5 | 1500 | 850 | 1867(2299) | Ø410 |

| CMC(E)-1500 | 160 | 250 | 11 | 1650 | 1400 | 1787(2077) | Ø410 |

| CMC(E)-2000 | 200 | 250 | 15 | 1650 | 1400 | 1807(2239) | Ø460 |

※ The numbers in parentheses indicate the height of CMCE models.

※ Specifications are subject to change for performance improvement.

Key Features

-

Centralized Oil Mist Collector

- Can be connected to multiple machining facilities to be used as a centralized oil mist collection system.

- Collected oil is gathered at the bottom due to gravity and can be discharged by opening a valve (recyclable).

- Equipped with a flow gauge for convenient monitoring of accumulated oil.

- Capable of removing non-water-soluble oil mist as well.

-

Three-stage Filter Structure

- The three-stage filter structure enhances particle removal efficiency and extends the life of the filter.

- Designed for filtration in the order of ① Pre-filter ② Veebag filter ③ Medium filter (CMCE only) to maximize filter performance.

-

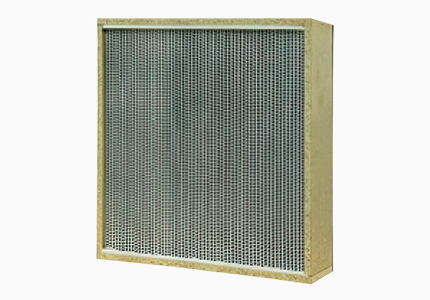

Stage 1: Pre Filter

- Equipped with a pre-filter to extend the life of the downstream high-performance filters.

- The polyester pre-filter removes larger particles as a first step.

-

Stage 2: Veebag Filter

- Secondary removal of particles not filtered by the first-stage pre-filter.

- The synthetic fiber Veebag filter efficiently removes particles with moisture and oil content.

-

Stage 3: Medium Filter (CMCE only)

- Secondary removal of particles not filtered by the pre-filter.

- The MEDIUM filter offers filtration efficiencies ranging from 65% to 95%, depending on MEDIA selection, making it a versatile mid to high-performance filter.

-

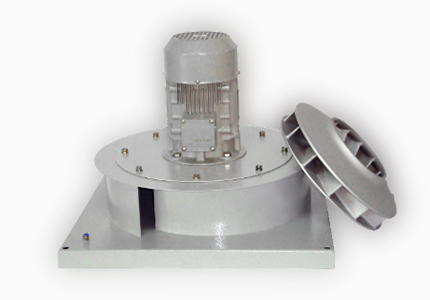

High-efficiency Turbofan

- Utilizes a durable high-efficiency turbofan for stable and superior suction performance.

- The impeller is precision balanced electronically to minimize vibration and noise.

Options (Optional)

-

Separator

- As a pretreatment device, the demister dramatically reduces the amount of oil collected by the dust collector, thereby extending the filter's life.

- Collected oil is gathered at the bottom due to gravity and can be discharged by opening a valve (recyclable).

- Capable of removing non-water-soluble oil mist as well.

-

German-made Analog Differential Pressure Gauge

- Equipped with an analog differential pressure gauge from AFRISO, a globally renowned German measuring instrument manufacturer, ensuring low maintenance and precise measurements.

- The differential pressure gauge helps identify filter clogging and indicates when replacement is necessary.

-

Control Box / Switchboard

- Switches, circuit breakers, and control devices are housed in a separate sheet metal box.

- The electrical control devices are protected from contaminants, extending their lifespan.

- Can be attached and used in the desired location.

-

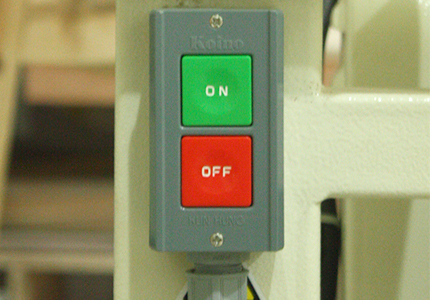

Local Switch, Contact Configuration

- Adds a local switch for turning the power ON/OFF.

- Can be attached and used in the desired location.

- The electrical circuit contacts can be configured to turn ON/OFF simultaneously with other equipment.

-

Flexible Conduit for Wiring

- Wires are covered with a flexible conduit to prevent damage to the insulation and reduce the risk of fire.

-

Filter Material Change

- For CMCE, the third-stage filter can be replaced with a different filter according to the characteristics of the contaminants.

- HEPA (High Efficiency Particulate Air) filter: A high-efficiency filter capable of removing 99.97% of particles as small as 0.3μm.

-

Customization / Custom Design

- Design changes or new developments to specifications other than standard products can be made upon request.

- Our company possesses the highest level of design responsiveness in the industry.

-

Power Specification Changes

- Options available for 220V/ 380V/ 440V, single-phase/three-phase, 50Hz/60Hz.

Cautions

-

- Do not inhale flammable substances such as gasoline or thinner.